Enterprise Resource Planning

The E.R.P. is a system that allows the control and the management of all the business processes and through which all the informative, organizational and operating system joins. The productive period has come to an end and is focused on creating strong stocks of products and raw materials. The fierce and growing demand of the past is now replaced by an increasingly variable and selective market, both in terms of quantity and preferences.

Producing excess quantities is a "privilege" that no one can afford anymore.

The E.R.P. is designed to produce and/or buy "fast" only when necessary, which means basing production and/or logistics on market demand, with a view to drastically reducing waste.

Today company must be considered as a extremely dynamic system, but at the same time the management of internal processes can not be based on little optimized or dispersive resources.

The possibilities offered by a progressive reduction in the costs of I.C.T. (Information and Communication Technologies), have allowed companies to invest in E.R.P. systems.

Manage your E.R.P. with Atena!

Atena is the ideal software to manage your ERP, where any cost or income is booked to an expenditure/income reference item: a system to manage in a synergic and personalized way all business processes.

Athena is a highly dynamic procedure, and goes beyond any kind of standardization. It is continuously developed by our programmers according to specific customer requests and following special and detailed analysis.

Strong points:

- Checking the progress of the work relating to the order

- Keep under control advance invoices issued or suppliers orders linked to the contract.

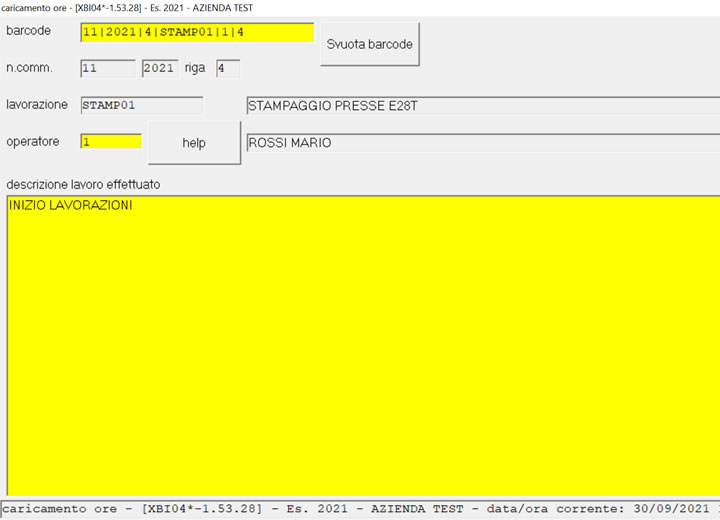

- Working hours of technicians visible in the worksheet executed and uploaded by the appropriate hours management program

- Worker entrance and exit with touchscreen workstation. Download PDF Brochure

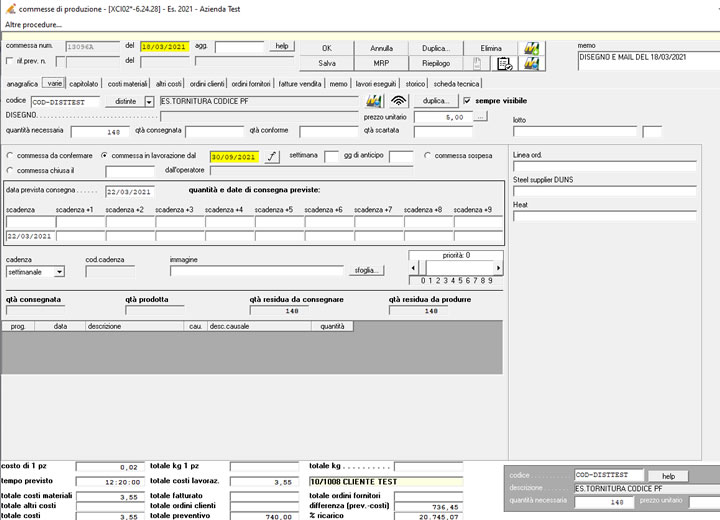

Production order

It is possible to add the finished product details (quantity, deadlines, processing management, etc...)

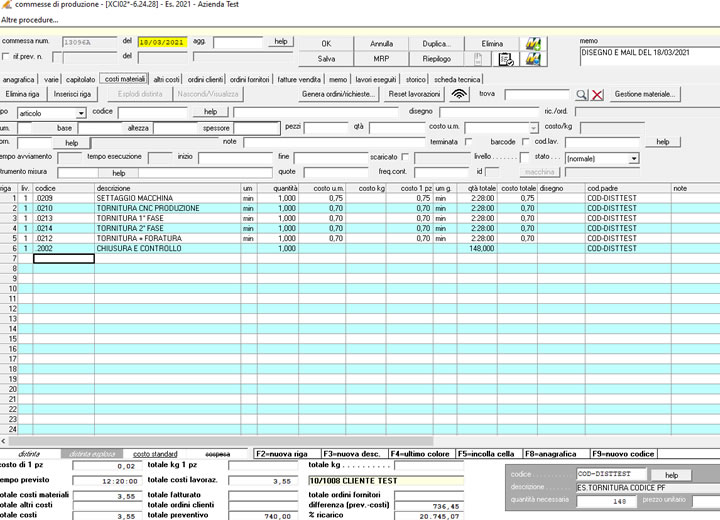

Charging

The cost section contains data on the components of the finished product. These data are recovered by the software if uploaded to the final product list, but they can be modified as needed. Otherwise, the user must indicate the codes that are used for the production of the finished code (taken from the stock code table, from the processing table or from the account plan).

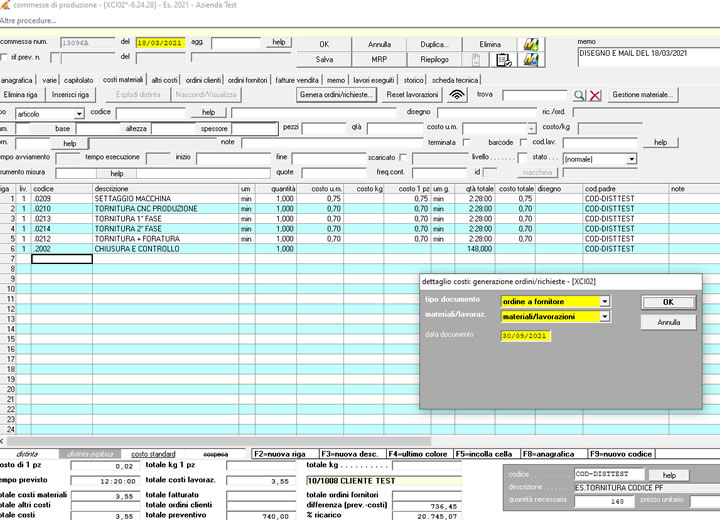

Document creation

It is possible to generate supplier orders, quotation requests or internal orders containing the rows of the costs section, both for materials and machining ( just in a descriptive way with the indication of the quality)

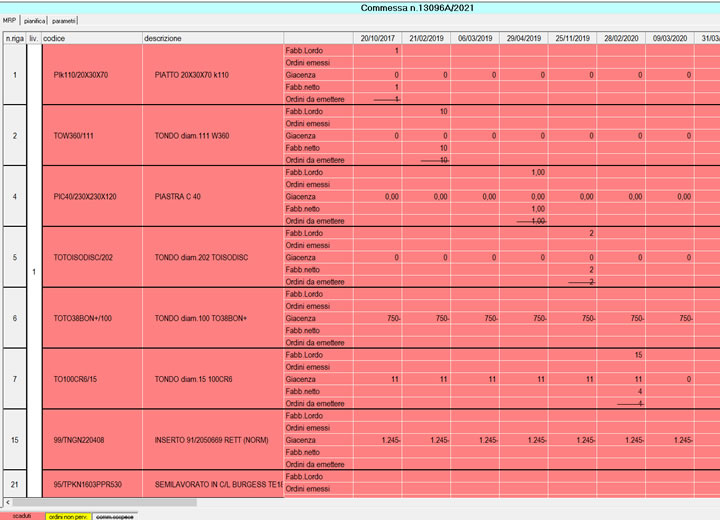

MRP

From this section you can configure which codes to value, hide codes that do not need a reorder and filter for a period.

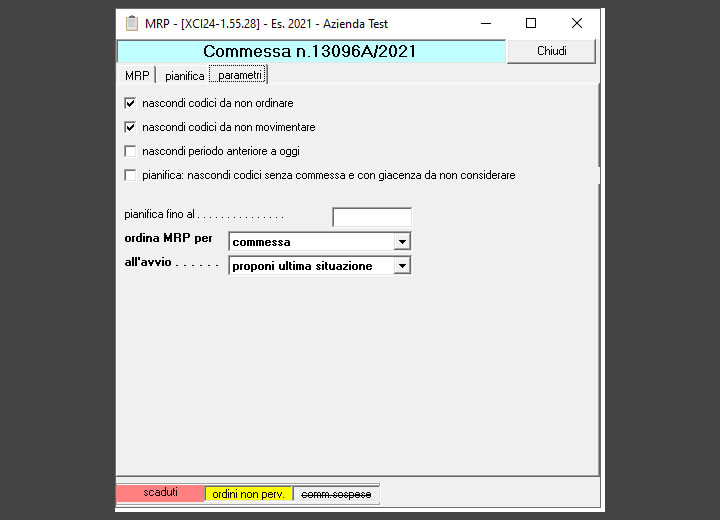

MRP parameters

From this section you can configure which codes to value, hide codes that do not need a reorder and filter for a period.

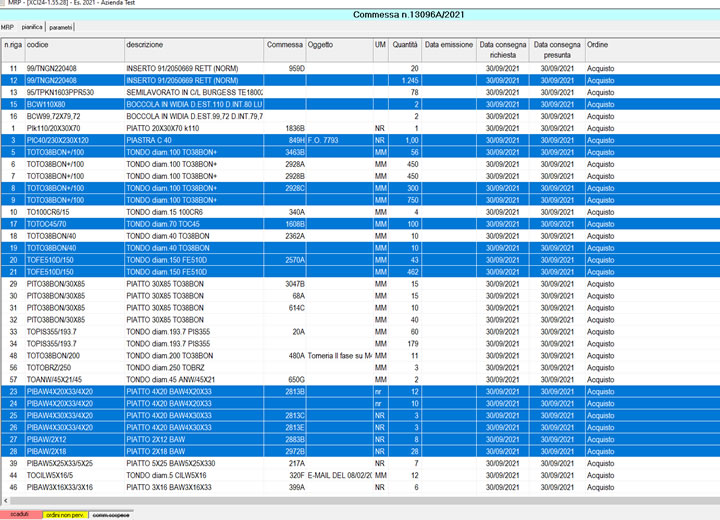

Plan MRP

The list shows the supplier orders and production orders to be crated based on the situation displayed on the MRP.// Our staff is available to provide you with the help you need